The answer is found in its heat resistance rating and recommended service temperature.

Once solely used for industrial purposes such as flooring and manufacturing, epoxy resin has become a popular material in recent years for woodworking, home, and art & craft projects. With so many brands and options available on the market, it can be challenging to know which epoxy meets your specific needs. One of the most important factors when making a purchase is resin heat resistance.

Is cured epoxy resin heat resistant?

Epoxy resin can withstand heat, yes, but the amount varies depending on the brand and the intended purpose. For example, Industrial Clear epoxy resin is formulated is ideal for normal use on surfaces like countertops, bar tops, tables, but will become damaged if exposed to high temperatures of a dish right out of the oven, for example.

If you apply heat to an epoxy resin not designed for high heat resistance, the surface will soften and then re-harden with potential indentations or a loss of shine. For this reason, it's always best to make sure the epoxy resin you're using is suitable for the project you intend to use it for. After all, you wouldn’t want coffee cup rings embedded in your tabletop because you didn't use an epoxy for high temperatures.

What are the top 5 applications of epoxy resin?

Does heat soften epoxy?

If cured epoxy is exposed to a temperature higher than it was designed to withstand, the resin will soften. In most cases, it will harden again without damage after cooling down, but there are instances where the resin may suffer irreparable damage such as warping, pooling, or indentations while it's still soft. Manufacturers determine the temperature limit of epoxy by testing its softening point or heat deflection point, which is closely related to the hardness and brittleness of the final product. An epoxy resin formulated to have a high temperature softening point will maintain its strength and smooth, high-gloss properties under high heat without softening.

At what temperature does epoxy melt?

The heat resistance refers to the temperature at which cured epoxy resin can essentially be melted into a catalyzed liquid, and for Industrial Clear, this number is 190ºF (88°C) or higher.

Can you put hot things on epoxy resin?

All epoxy resin has a recommended service temperature, indicating the temperature at which a resin coating can withstand heat from an object placed on it without damaging the surface. (Note that this is not the same as heat resistance, which refers to the temperature at which epoxy resin can melt.)

The recommended service temperature is usually expressed in terms of specific uses. For example, rather than specifying the exact temperature of a hot cup of coffee, which is around 134ºF / 56ºC, it's better to indicate that the product is appropriate for a hot cup of coffee.

Industrial Clear's recommended service temperature can handle something as hot as a cup of coffee without causing damage to the surface, but may not be able to withstand something as hot as a casserole dish straight out of the oven.

Just like laminate, quartz, granite, and butcher block,Industrial Clear can be used to coat countertops when combined with hot plates.

What can reduce Temperature Resistance?

Not following the label instructions accurately when working with epoxy resin can compromise its temperature resistance ratings. For the best outcome and to maintain the integrity of the epoxy resin, it's essential to follow the instructions properly.

When preparing Industrial Clear, follow the proper 2:1 mixing ratio of resin to hardener, measuring precisely and stirring thoroughly. For all epoxy resins and regardless of cure time, it's best to wait seven days before using a coated surface so that the final 1% of curing can occur, allowing the resin to reach its full, accurate heat and hardness profile.

Is epoxy flame resistant?

Industrial Clear epoxy resin is flame resistant in its liquid state. It does not contain combustible ingredients or solvents that could potentially ignite when exposed to heat. It is considered stable and non-reactive, even under fire conditions. For these reasons, Industrial Clear is classified as a non-hazardous material for transportation.

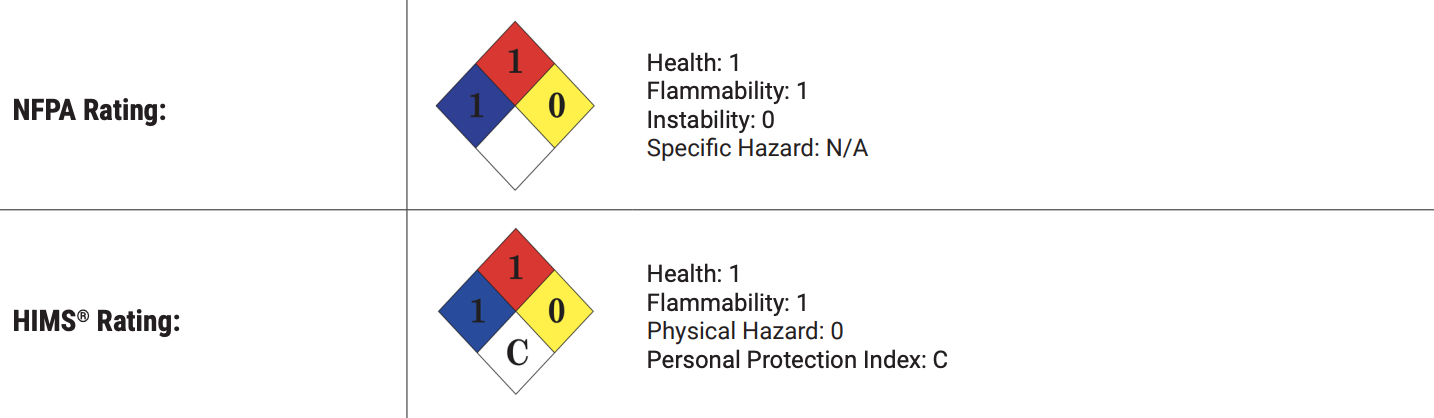

Always consult the Safety Data Sheet (SDS) for the epoxy resin you're using for information on flammability and other safety considerations. Industrial Clear's SDS includes the National Fire Protection Association (NFPA) and the Hazardous Materials Identification System (HMIS) diamonds. These rating systems indicate health, flammability, reactivity, and physical hazards on a scale from 0 (no hazard) to 4 (high hazard). HMIS also indicates what personal protection equipment should be used when working with Industrial Clear.

Industrial Clear's NFPA Rating:

- Health: 1 indicates that the product is not considered toxic. It could cause irritation but only minor residual injury, even if no treatment is given.

- Flammability: 1 indicates that the product requires considerable preheating before ignition can occur.

- Instability: 0 indicates that the product is normally stable, even under fire conditions, is non-explosive and will not react with water.

-

Specific Hazards: this denotes that the product has no specific hazards.

Industrial Clear's HMIS® Rating:

- Health: 1 indicates that irritation or minor reversible injury is possible.

- Flammability: 1 indicates that the product requires considerable preheating before ignition can occur.

- Physical Hazard: 0 indicates that the product is normally stable, even under fire conditions, is non-explosive and will not react with water.

- Personal Protection Index: C represents that safety glasses, gloves and an apron should be used when working with the product.

Is 2 part epoxy heat resistant?

Industrial Clear 2 part epoxy resin is non-flammable in its liquid form. However, once the two components are mixed, the resin will start to catalyze and generate heat. It is important to ensure that the resin doesn't overheat as it starts to cure. While warmer temperatures can facilitate the curing process, if the resin gets too hot too quickly, it can lead to an exothermic reaction (flash cure), which can cause the resin to cure instantly, crack, and produce smoke.

Here are the most common reasons why resin can overheat:

Heat Build Up

Mixing too much resin at once, leaving resin to sit in the mixing cup for too long, or pouring too thick a layer can all cause an excessive heat build up, resulting in an exothermic reaction.

Working in the heat

Working in a hot environment can also trigger a flash cure, which is why it's recommended to work in temperatures between 70-80ºF (21-27ºC) and avoid pouring resin in temperatures above 95ºF (35ºC).

A hot water bath

When working with cold resin, it's essential to bring it up to room temperature to restore its viscosity and make it easier to work with. A warm water bath can help achieve this, but it's important not to use boiling water as it will make the resin and hardener far too hot, causing them to cure instantly when mixed. The water should only be warm, like a baby's bath.

Tips and tricks for heat resistant epoxy resin

For optimal results when working with epoxy resin, it's important to follow the label directions accurately. Not following the instructions may result in curing issues or a project that falls short of your expectations.

-

Prepare your work space so that pouring it is the only thing you need to do once you've measured and mixed: line the worktop and floor with plastic drop sheets in case of drips or accidental spills, ensure you have plenty of gloves available and a garbage bin close by. Have all the tools you'll need on hand including a spreader and torch. If you're using tints, ensure you have plastic cups and mixing sticks for each color you intend to use. Ensure your piece is clean, dry, and free of dust. Tape off the edges if required, level and prop the piece up and off of the work surface if necessary. Either have a large enough dustcover or a plan in place to protect the wet resin from dust as it cures.

-

Measure accurately and mix thoroughly. Industrial Clear is a 2:1 epoxy resin, so ensure you're measuring 2 parts of resin to 1 part hardener. Mix for at least 4 minutes, scraping the sides and bottom of the mixing container very well. Do not scrape the container as you pour in case there is unmixed product stuck to the sides of the mixing container.

-

Work slightly above standard room temperature: 70-80ºF or 21-27ºC is ideal. Humidity should be below 80% and ideally below 50% for optimal results.

-

Industrial Clear has a working time of 45 minutes. To ensure that you work efficiently within this timeframe, it's recommended to only mix the amount of resin you need for your project. If you have an exceptionally large piece, an extra pair of hands to help mix, pour and spread is a good idea.

-

Industrial Clear is non-toxic and food safe when used as directed. Be aware that adding colorants that are not designated non-toxic will compromise Industrial Clear's food safety and non-toxicity designations. If you intend to use your tinted resin piece for direct contact with food, we recommend applying a coat of clear, untinted resin as a final top coat.

-

Keep a spray bottle of isopropyl alcohol and a roll of paper towel on hand for cleaning sticky tools or drips.

- Industrial Clear is dry to the touch at 24 hours and fully cured in 7 days. For best results, allow the resin to fully cure and reach its maximum hardness before putting your project into use.

We hope that this information will give you the confidence to use Industrial Clear Epoxy Resin on your table, bar top or counter to create something beautiful, functional and durable.